(Article

begins on the Tech, Tests & Installs page HERE)

About

Different Axle Designs

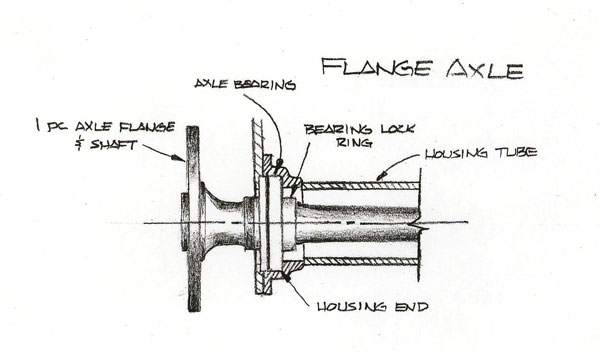

Flange Axle Design

- The most common flange axle design has a single piece

axle, flange and shaft. The axle bearing has a press fit

on to the axle shaft and a bearing lock ring is then pressed

on behind the bearing. Housing ends are welded to the housing

tube and the bearing slips into the housing end. The bearing

is then retained by the caliper mounting bracket. Wheel

studs are installed in the flange of the axle where the

wheel bolts directly to the outside of the axle flange.

With this design the axle and axle bearings must support

not only the vehicle’s weight and torsional loads,

but also the bending loads from acceleration (rear wheels

try to “toe-in” during acceleration).

Safety

- In the event of an axle failure the axle along with the

wheel and tire can separate from the vehicle. In the case

of a break outboard of the bearing, the wheel will definitely

come off. A break inboard of the bearing and the wheel will

stay on only until the caliper mount breaks and the bearing

is free to come out of the housing end. This will also take

out the rear brakes and the caliper and brake lines will

be torn off.

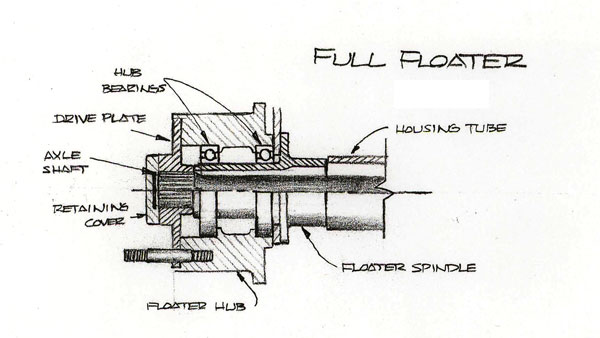

Full Floater Design

- The full floater design incorporates a hub with a bearing

installed in each end. Wheel studs are installed into this

hub and the assembled hub is then slipped on to the floater

spindle. The floater spindle is then welded to the housing

tube. The floater spindles are tubular and are large enough

for the axle shaft to pass through. The drive plate is splined

in the center and slides over the wheel studs and seats against

the hub. The axle shaft is splined on both ends, one end engages

the drive plate and the other end engages spool in the thirdmember.

With a full floater the axle shaft only sees torsional loads

since the wheel and tire are bolted to the floater hubs, which

are independent of the axle shaft. All other loads are taken

in the hubs and floater spindles Safety

- In the event of an axle failure the wheel and tire will

remain with the vehicle (as stated earlier the axle is independent

of the flange and hub which are mounted on the floater spindle).

The rear brakes would not be affected by axle breakage.

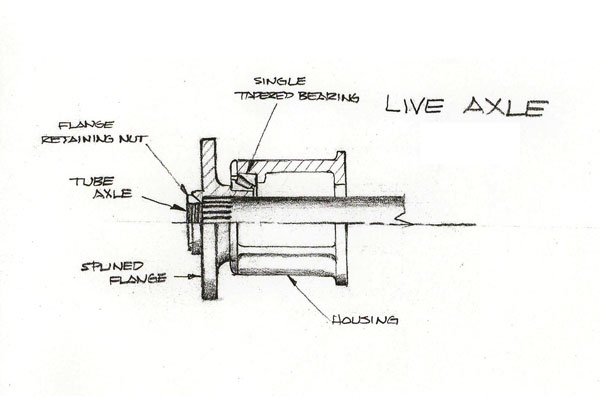

Live Axle Design

- With this design the axle shaft is a large diameter, thin

wall tube and becomes more of a structural member. The shaft

is splined in the center to engage the spool and splined

on both ends to accept a splined flange on each end. Both

ends have a threaded area for the flange retaining nut.

Most live axles use a single tapered roller bearing on each

end, which must be preloaded with the flange retaining nuts

during assembly. This design is most commonly found in Top

Fuel car applications. With this design the axle shaft must

carry all the load.

Safety

- As is the case with the flange axle, in the event of an

axle failure (unlikely due to the size of the axle) the

wheel and tire can separate from the vehicle. This would

also take out the rear brakes and the caliper and brake

lines would be torn off.

Source:

Mark Williams Enterprises

www.MarkWilliams.com

|