(More

tech articles on the Tech, Tests & Installs page HERE)

As

racers, we're always looking to go fast, but slowing safely

is actually much more important. Additionally, for the

footbrakers among us, it's the braking system that holds

the car at the starting line as we're way up on the converter.

That's why when I saw this technical piece about brake

systems on the website of Mark

Williams Enterprises, I knew I had to share

it here with you. The article discusses Pedal Ratio &

Master Cylinder, Master Cylinder Selection, Caliper Alignment

Clearance and Position, Proportioning Valves, Brake Lines

and Fluid, and Troubleshooting. As

racers, we're always looking to go fast, but slowing safely

is actually much more important. Additionally, for the

footbrakers among us, it's the braking system that holds

the car at the starting line as we're way up on the converter.

That's why when I saw this technical piece about brake

systems on the website of Mark

Williams Enterprises, I knew I had to share

it here with you. The article discusses Pedal Ratio &

Master Cylinder, Master Cylinder Selection, Caliper Alignment

Clearance and Position, Proportioning Valves, Brake Lines

and Fluid, and Troubleshooting.

|

Pedal

Ratio & Master Cylinder

________________________________________

Mounting the master cylinder to a frame

rail or roll bar is recommended to ensure a solid mount.

With the correct master cylinder in place, the pedal ratio

must be great enough to produce 1200 psi system pressure

under severe braking conditions. A pedal ratio versus

line pressure calculator is available here.

We recommend using a pressure gauge connected to the system

to verify the maximum available pressure before running

the car. If the desired pressure can not be easily attained

the pedal ratio must be increased until the minimum pressure

of 1000 psi is easily reached.

Master

Cylinder Selection

________________________________________

A

common problem in many applications is a spongy pedal.

Brake systems inherently have slack in the system that

must be taken up before work can be done by the pads.

Slack comes from two factors: retracted pistons must be

moved back out, and misalignment caused by deflection

in the axle and housing mis-alignment. One of the most

common misconceptions is that a larger master cylinder

will create more pressure. While a larger master cylinder

creates a larger displacement, it takes more force to

create the same pressure as a smaller bore. While a larger

master cylinder will take up system slack with less pedal

stroke, it will take more force to create the same system

pressure. The result after adding the larger master cylinder

is a harder pedal which needs much more pedal pressure

to create the same amount of braking force. For instance,

moving from a 3/4" master cylinder to a 1" requires

77.7% more force on the push rod. A

common problem in many applications is a spongy pedal.

Brake systems inherently have slack in the system that

must be taken up before work can be done by the pads.

Slack comes from two factors: retracted pistons must be

moved back out, and misalignment caused by deflection

in the axle and housing mis-alignment. One of the most

common misconceptions is that a larger master cylinder

will create more pressure. While a larger master cylinder

creates a larger displacement, it takes more force to

create the same pressure as a smaller bore. While a larger

master cylinder will take up system slack with less pedal

stroke, it will take more force to create the same system

pressure. The result after adding the larger master cylinder

is a harder pedal which needs much more pedal pressure

to create the same amount of braking force. For instance,

moving from a 3/4" master cylinder to a 1" requires

77.7% more force on the push rod.

The

goal then is to balance the entire system. Pedal force,

system pressure and lever travel all need to be taken

into account. A balanced system includes the following

things:

1)

A lever that moves the entire stroke of the master cylinder

2) A Lever that moves comfortably in the confines of a car

3) Uses a reasonable amount of force to reach the desired

system pressure

4) Is aligned well enough to minimize lever travel

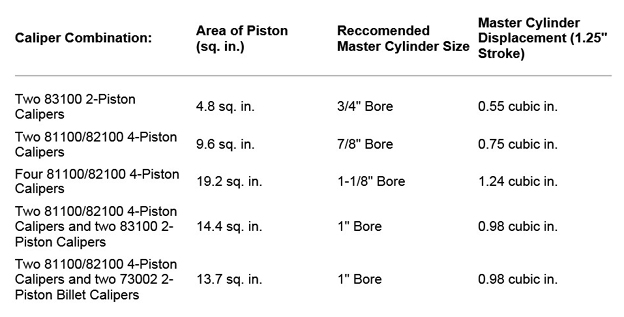

Use

the calculator

to help you find the correct ratios. First find the correct

caliper combination from the chart, then find the correct

ratio for your master cylinder size.

Caliper

Alignment Clearance and Position

________________________________________

Axle stand out controls the alignment of

the brake system and as a result is extremely critical.

To check stand out, first verify that the housing ends

are square to the tube and axles. Install the axles and

check axle standout (face of axle flange to face of housing

end) as accurately as possible. See the chart below for

stand out dimensions for MW brake kits. Stand out should

be + .015 of the dimension listed. Shims are available

to correct the alignment moving the disc outward .015”

(MW

catalog page 62 or online

P/N 71009). Misalignment can cause caliper mount deflection

which is one of the causes of a “spongy” pedal.

Install your wheels to make sure the caliper to wheel

clearance is adequate both radially and from outer face

of the caliper to the inner face of the wheel. To bleed

the system, the calipers must be positioned at 3 or 9

o’clock. This allows the bleeder to be highest point,

ensuring that all air is removed from system.

Common

Standouts

________________________________________

Proportioning

(Pressure Reducing) Valve

________________________________________

The front brake kits with the integral

hub and adaptor are designed for Drag Race applications.

The main advantage is the reduction of weight compared

to the stock braking system they are designed to replace.

Several considerations must be taken into account when

installing these kits. When any four piston caliper is

used with drum brakes on the rear, a pressure reducing

valve must be installed for front pressure control. Because

of the small front tire contact area compared to the rear

large slick contact area, the rear brakes must absorb

more of the stopping energy than the front (contrary to

a normal street car). A starting point would be 70% of

the rear line pressure to the front brakes. This is especially

important when using drum brakes on the rear. With discs

on both the front and rear the percentage could be higher

depending on the weight distribution and tire size but

should still use the pressure reducing valve. We have

a pressure reducing valve, P/N

260-2200, and we recommend its installation with front

brakes. The pressure bias should be adjusted with gauges,

MW

P/N 81105, in the front and rear to confirm the pressure

differential and then do a stop test. When doing a stop

test, for a drag race car, the front tires should skid

equally or slightly after the rear tires. This test can

be simulated at a very low speed (approximately 5 mph)

by using a wet surface or gravel and observing the lock

up sequence.

Brake

Lines and Fluid

________________________________________

Aircraft AN-3 brake lines and fittings

are recommended. Only stainless steel braided teflon hose,

stainless or seamless steel tubing (3/16” x .028”)

should be used for brake lines. MW has available swaged

Teflon Stainless flexible braided line that can be fabricated

on a same day basis. The are available online P/N

0300-X-X. Lines should be secured to chassis rails

to resist vibration and routed in such a way to avoid

possible contact with wheels, tires and other moving parts.

Joining hard line and braided line or “T”s

should be done using a bulkhead fitting and a small tab

welded to the chassis. Long runs should be done with hard

tubing to avoid expansion of flexible line. The amount

of flexible braided hose in the system should be kept

to a minimum. See page

63 or the online

store for AN -3 fittings and brake line. Use of DOT

4 or 5.1 fluid with a high boiling point and lubrication

for seals and pistons is recommended. Do not use (DOT

5) silicone fluids .

Troubleshooting

Your Brakes

________________________________________

Spongy

Pedal:

________________________________________

1) Air in system. Bleed brakes, making

sure that the bleed valve is the highest point.

2) Disc warped (saucer shaped). Replace or surface rotors

3) Calipers not square with disc. Check housing end alignment,

both concentricity and squareness.

4) Linings worn on taper. Make sure that caliper is centered

over the rotor and the caliper bracket is not deflecting.

5) Master cylinder bore too small creating excessive high

line pressure. Match master cylinder to system.

6) Master cylinder deflection. Stiffen master cylinder

mounts

Brakes

are locked up after run:

________________________________________

The piston in the master cylinder is not

being allowed to return to the full retract location,

when released. This condition will maintains line pressure

and prevents the car from moving. Re-adjust the linkage

so that the piston completely returns to the retract location.

Excessive

pad wear, disc shows excess heat:

________________________________________

1) Lining too thin causing rapid heat transfer

to calipers, boiling the fluid. Install new linings and

re-bleed system.

2) Fluid contaminated with moisture causing boiling of

fluid in caliper. Flush old fluid and replace with DOT

5.1 Fluid re-bleed system.

Maintenance:

________________________________________

Annual disassembly and cleaning of brake

system recommended. Carefully inspect pistons and piston

bores. Re-assemble with new “O” rings.

|

|

Source:

Mark Williams Enterprises

www.MarkWilliams.com

|

Dragtime

News On Location |

Tech,

Tests & Installs |

Bracket

Racing 101 |

|

|

Visit

the Tech,

Tests & Installs main page. |

Visit

the Bracket

Racing 101 main page.

|

|

|

|

|

|

|