Start

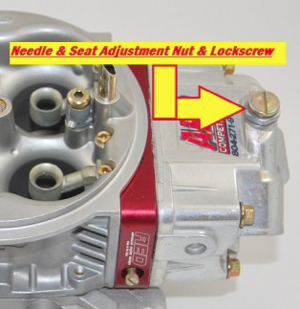

the engine and check float level adjustment –

The level should be ½ - ¾ of the way up

in the sight window. The level can be adjusted with

the nut & lockscrew on top of each bowl. If you

want to raise the level, gently loosen the nut about

a ½ turn and re-tighten the lockscrew. Re-check

the level and repeat as needed. If you want to lower

the level, you will need to loosen the nut slightly

to break the lockscrew loose, then tighten the nut a

½ turn and re-tighten the lockscrew and repeat

as needed. Be sure you hold the lockscrew still as you

tighten the nut to ensure the float height will change

accordingly.

Start

the engine and check float level adjustment –

The level should be ½ - ¾ of the way up

in the sight window. The level can be adjusted with

the nut & lockscrew on top of each bowl. If you

want to raise the level, gently loosen the nut about

a ½ turn and re-tighten the lockscrew. Re-check

the level and repeat as needed. If you want to lower

the level, you will need to loosen the nut slightly

to break the lockscrew loose, then tighten the nut a

½ turn and re-tighten the lockscrew and repeat

as needed. Be sure you hold the lockscrew still as you

tighten the nut to ensure the float height will change

accordingly.

Check

the engine’s idle speed. If you want to raise

the idle speed, simply tighten the primary idle speed

screw. To lower the idle speed, loosen the idle speed

screw.

Check

the engine’s idle speed. If you want to raise

the idle speed, simply tighten the primary idle speed

screw. To lower the idle speed, loosen the idle speed

screw.

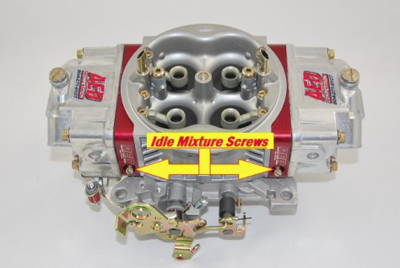

The

idle mixture screws will be the next adjustment to check.

These 4 screws control the amount of fuel given to the

engine @ idle. The easiest way to remember how these

work is to think of them as a water faucet/spigot on

the side of you house. The more you loosen the handle,

the faster the water comes out. On the other hand, the

more the handle is tightened, you turn the water off.

These mixture screws function in exactly the same fashion.

The most important thing is to be sure what ever changes

you make to 1 corner of the carburetor, the other 3

will need to follow suit. This will ensure equal distribution

and help eliminate drivability issues as well.

The

idle mixture screws will be the next adjustment to check.

These 4 screws control the amount of fuel given to the

engine @ idle. The easiest way to remember how these

work is to think of them as a water faucet/spigot on

the side of you house. The more you loosen the handle,

the faster the water comes out. On the other hand, the

more the handle is tightened, you turn the water off.

These mixture screws function in exactly the same fashion.

The most important thing is to be sure what ever changes

you make to 1 corner of the carburetor, the other 3

will need to follow suit. This will ensure equal distribution

and help eliminate drivability issues as well.

To

richen the idle, loosen all 4 screws equally about ¼

- ½ turn each. Re-check idle quality and repeat

as needed.

If

the idle is too rich initially, you will need to lean

the idle by tightening the 4 screws equally about ¼

- ½ turn each. Re-check idle quality and repeat

as needed. Be careful not to overtighten the idle mixture

screws as this can damage the needle tip. It is perfectly

normal for idle speed to vary as you change the idle

mixture screw adjustment. If idle speed varies greatly

from the desired idle speed while making adjustments,

adjust primary idle screw as needed after setting all

4 screws equally.

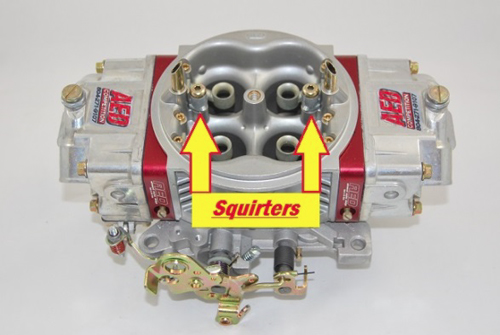

The

accelerator pump nozzles or “squirters”

are sized according to the size of the carburetor. Different

intake and cylinder head combinations may require more

or less pump shot. If the engine seems to have an off-idle

stumble, changing the size of the squirter itself can

fix this issue.

The

accelerator pump nozzles or “squirters”

are sized according to the size of the carburetor. Different

intake and cylinder head combinations may require more

or less pump shot. If the engine seems to have an off-idle

stumble, changing the size of the squirter itself can

fix this issue.

The

first thing to do is determine whether it’s a

lean or a rich stumble. If the engine seems to take

a deep breath and then accelerate quickly (almost like

the ignition cuts off for a split second), it’s

generally a lean stumble. Check the size of the squirter

on the primary side and install the next largest size.

If that seems to help, but not completely eliminate

it, try increasing the size of the secondary squirter.

If

the engine seems to have a “blubber” or

is lazy to accelerate then cleans up as it builds RPM,

it’s generally a rich stumble. Check the size

of the squirter on the primary side and install the

next smallest size. If that seems to help, but not completely

eliminate it try decreasing the size of the secondary

squirter.